Moarconn's R&D team is a 10-member elite team consisting of senior industry experts, technical backbones and young talents. With their deep understanding of connector technology and keen insight into the demand of market, they continue to promote product innovation and development. The team members have an average of more than 8 years of product development experience and professional knowledge, and have a high sense of responsibility and sense of mission. They are committed to providing customers with the highest quality card connector and solutions of it.

Research and Development for Card Connector

Provide card connector solutions for you from product mold design & mold making.

Exploring Infinite Possibilities. Forging a Connected Future.

Precision Plastic Mold Design & Manufacturing

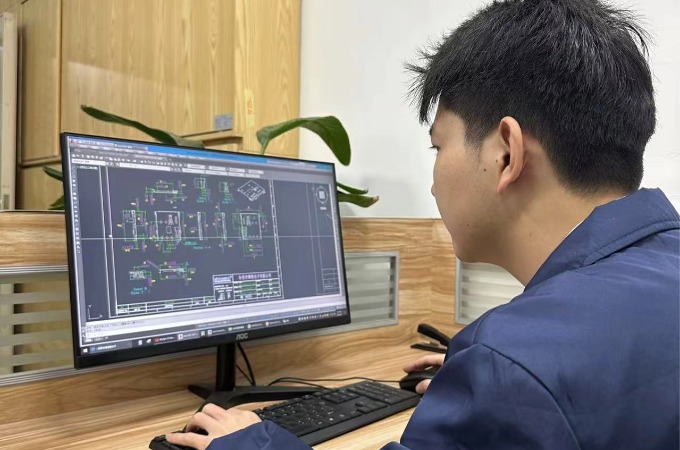

Moarconn has 8 hardware and plastic moulding design engineers with more than 10 years‘ experience in connector’s design, and we will use advanced CAD, CAM and other design software to ensure the high precision design of the moulds, to ensure that the dimensions of the card connectors are accurate and meet the strict tolerance requirement.

Moarconn has independent assembly workshop of plastic mould and hardware mould and 10 mould engineers to ensure the efficient manufacturing capability of hardware mould and plastic mould, thus to shorten the development cycle of card connector effectively.

The mould design capability and manufacturing capability of hardware & plastics are played a vital role in the production of card connectors. High precision mould design, efficient mould processing and manufacturing provide a stronger guarantee for the quality, cost and delivery of the connectors.

Precision Punching Mold Design & Manufacturing

Moarconn has 6 hardware moulding design engineers with more than 10 years‘ experience in connector’s design, and we will use advanced CAD, CAM and other design software to ensure the high precision design of the moulds, to ensure that the dimensions of the card connectors are accurate and meet the strict tolerance requirement.

Moarconn has independent assembly workshop hardware mould and 6 mould engineers to ensure the efficient manufacturing capability of hardware mould, thus to shorten the development cycle of card connector effectively.

The mould design capability and manufacturing capability of hardware are played a vital role in the production of card connectors. High precision mould design, efficient mould processing and manufacturing provide a stronger guarantee for the quality, cost and delivery of the connectors.

Automation Equipment Design & Manufacturing

Moarconn has 6 Automation Equipment Design engineers with more than 8 years experience in molding design, and we will use advanced CAD, CAM and other design software to ensure the high precision design of the moulds.

Automation design involves creating systems or processes that can operate automatically with minimal human intervention. The goal is to improve effciency, reduce errors and increase productivity.

Manufacturing automated assembly lines, quality control systems.

Moarconn has independent assembly workshop of plastic mould and hardware mould and 10 mould engineers to ensure the efficient manufacturing capability of hardware mould and plastic mould, thus to shorten the development cycle of card connector effectively.

The mould design capability and manufacturing capability of hardware & plastics are played a vital role in the production of card connectors. High precision mould design, efficient mould processing and manufacturing provide a stronger guarantee for the quality, cost and delivery of the connectors.

Moarconn R&D Testing Laboratory

Moarconn has R&D team has mastered the advanced testing techniques for card connectors. They are proficient in testing equipment, so they can optimize products efficiently. The team also has strong simulation and analysis capabilities to accurately predict the performance and reliability of the product to ensure that the product performance is excellent in real-world applications.

Innovation is one of the core competencies of our R&D team. They are constantly exploring new design concepts, materials and processes to improve the performance and quality of our card connectors. Technical exchanges and innovation-related seminars are often held within the team. We encourage our members to come up with new ideas and solutions. It is this continuous innovation and improvement that makes our card connector have strong competitiveness in the market.

R&D Results

Our R&D team has successfully developed a series of high-performance and high-reliability card connectors. These products are widely used in communications, automobiles, medical, industrial and other fields, and have been widely recognized by the market and customers. Behind these achievements are countless attempts, improvements and polishing by the Maokang R&D team, and the pursuit and persistence of excellence in technology.

8Invention patents

25Utility model patents

More CertificatesQuickly Customized Card Socket Connector For You

Free provide quotation within 2 hours

Free provide design scheme within 48 Hours

From product design to initial sample within 25 days

- Quick Quotation

- For Dealer

- Mobile Phone

- Mobile Phone

Global Partners

- Mobile Phone

- *Title

- *Content