Industrial Controller

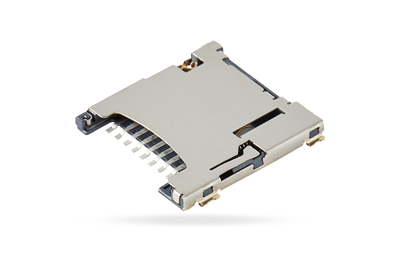

PLCs and other controllers are used to control and monitor production processes. Then, the SD card connector can be used to stored procedure, configuration files and data.

PLCs and other controllers are used to control and monitor production processes. Then, the SD card connector can be used to stored procedure, configuration files and data.

SD card connectors in system of SCADA and other monitoring devices are used to store historical data, reports and files.

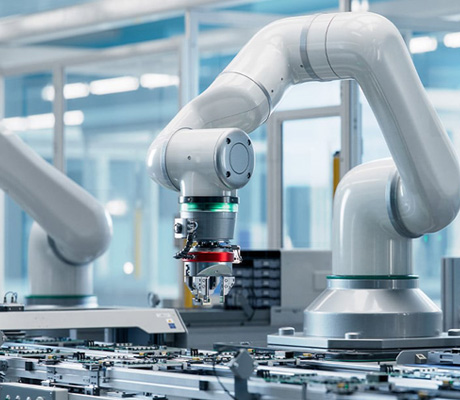

Micro SD card connectors are used in industrial robots to store trajectories, procedure and data.

These devices are usually installed in places far away from the habitation of human or difficult to access, such as oil fields, mines, wind farms in remote areas. Remote monitoring and control can be fulfilled through the use of SIM card connectors on these devices. Data in real time can be transmitted in real time to a central control system for real-time monitoring, troubleshooting and remote control.

Industrial equipment is usually required to run for a long time, so the durability and stability of the card connectors are required to be high. If the quality of the card connector is not good, it is easy to have poor contact, loose or damaged, thus affecting the normal operation of the equipment.

The industrial environment may be affected by temperature, humidity, vibration and other factors. A good connector is needed to have a good environmental adaptability, so that even in poor working conditions can maintain a stable connection performance.

Card connectors in industrial equipment undertake important electrical connection tasks, so reliability and safety are critical. Any failure of the card connector may lead to equipment downtime, resulting in production losses and even safety accidents.

Aiming at the pain points faced by industrial equipment when using card connectors, Moarconn, as a professional card connector manufacturer, will provide you with the following effective solutions:

Our card connectors are made of high-quality materials and advanced manufacturing process to ensure that the card connectors are had excellent durability and stability, and can operate for a long time without damage.

We conduct engineering design and rigorous testing to ensure that the card connectors can be adapted to the needs of various working environments, including temperature, humidity, vibration and other factors, to ensure the stability of the product in harsh conditions.

We implement a strict quality control system to ensure that each card connector is meeted the relevant industry standards and certification requirements, to provide you with reliable product quality and performance assurance.

We implement a strict quality control system to ensure that each card connector is meeted the relevant industry standards and certification requirements, to provide you with reliable product quality and performance assurance.

In industrial environments, equipment needs to run for long periods of time without interruption. As a key component inside the equipment, the operation of the whole equipment is directly affected by the stability and reliability of the card connector. Card connectors developed and produced by Moarconn that can withstand a variety of industrial environments to ensure stable equipment operation.

With the popularity of Industry 4.0 and the Internet of Things (IoT), the demand for transferring data in industrial equipment is getting higher and higher. The maximum read/write speed of the card connector developed and produced by Moarconn can reach 4GB/s, which can support high-speed and high-efficiency data transmission and help industrial equipment real-time data monitoring, remote control and other functions.